To achieve this, there must be sufficient sugar available and fermentation must occur as quickly as possible and air must be excluded throughout (anaerobic conditions). This can be done in a silage clamp or in big bales. Both have the same objectives:

- Rapid removal of air (compaction)

- Rapid fermentation of grass sugars to lactic acid

- Maintenance of anaerobic conditions in the clamp/bale during storage

- Growing and harvesting factors influencing forage quality.

Wilting

Rapid wilt (24 hours maximum) to about 30% DM to reduce effluent and concentrate sugars if conditions permit. As a guideline, 1% of moisture is lost per hour of sunlight in bright conditions. It can be greater with mower-conditioners and tedding. When wilting, remember that high DM grass (35%+) has a greater risk of mould. Wilting for 12 hours or more has become standard practice to reach the higher dry matter silage required by the modern dairy cow. However, longer wilting results in the proliferation of spoilage organisms, leading to the loss of valuable nutrients.

Ecosyl 100 - is ideal for a wide range of crops and ensiling conditions. It has been thoroughly proven to better fermentation and animal performance. Ecosyl 100 contains MTD/1 - a special strain of bacteria which is only found in the Ecosyl range of silage additives.

Ecosyl 100 - is ideal for a wide range of crops and ensiling conditions. It has been thoroughly proven to better fermentation and animal performance. Ecosyl 100 contains MTD/1 - a special strain of bacteria which is only found in the Ecosyl range of silage additives.

Features and Benefits

- 3 ‘D’ extra digestibility

- Improves animal performance

- Increased dry matter retention

Mixing and application

- Ecosyl 100 is available for a liquid or dry application

- One bottle/bag treats 100t of forage

- Any applicator – standard to ULV

- Apply from 20 ml/t to 2 l/t

- Dry application at 200 g/t

- GMO free and suitable for organic use

How do I ensure good preservation?

Poorly preserved silage could lose up to 5% units of DMD and have low intake characteristics. Therefore:

- Only attempt to wilt a crop if it will be genuinely drying while on the ground. A successfully wilted crop will preserve properly.

- If using an additive, ensure the full rate of an appropriate product is applied evenly.

- Harvest the grass free of contamination by dirt.

- Fill the silo quickly and seal perfectly (or wrap bale perfectly) in order to achieve the air-free conditions that are necessary for good preservation and to prevent mould growth.

- Ensure any effluent can quickly escape from the silo and is safely collected.

Pit management:

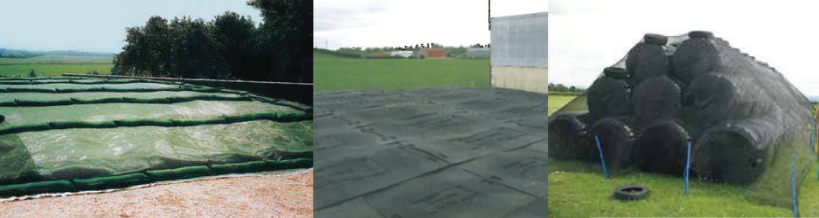

- Seal grass carefully beneath 2 sheets of black 0.125mm polythene.

- Cover completely with a layer of car tyres, placed edge-to-edge. Seal the edges with a layer of sandbags, silt, etc.

- As the silage sinks in the silo during the following week or two, check the plastic seal to ensure air is not getting in.

Inspect the plastic cover frequently and immediately repair any damage. Manage the silage appropriately during feed out to prevent heating losses, as any such losses will reduce silage digestibility.

Article written by Nigel Scally Drummonds Clonee/Rathcoffey.